SAP Integrated Business

planning

SAP Integrated Business

planning

What is SAP Integrated Business Planning for

Supply Chain?

Powered by SAP HANA, this cloud-based solution combines sales and operations planning (S&OP), forecasting and demand, response and supply, demand-driven replenishment, and inventory planning.

- Automated, tightly coordinated supply chain planning processes

- Advanced machine learning algorithms and planning capabilities

- Native integration with SAP Supply Chain Control Tower and other solutions

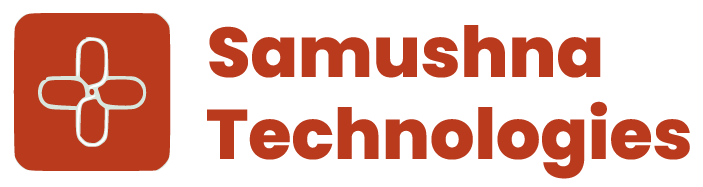

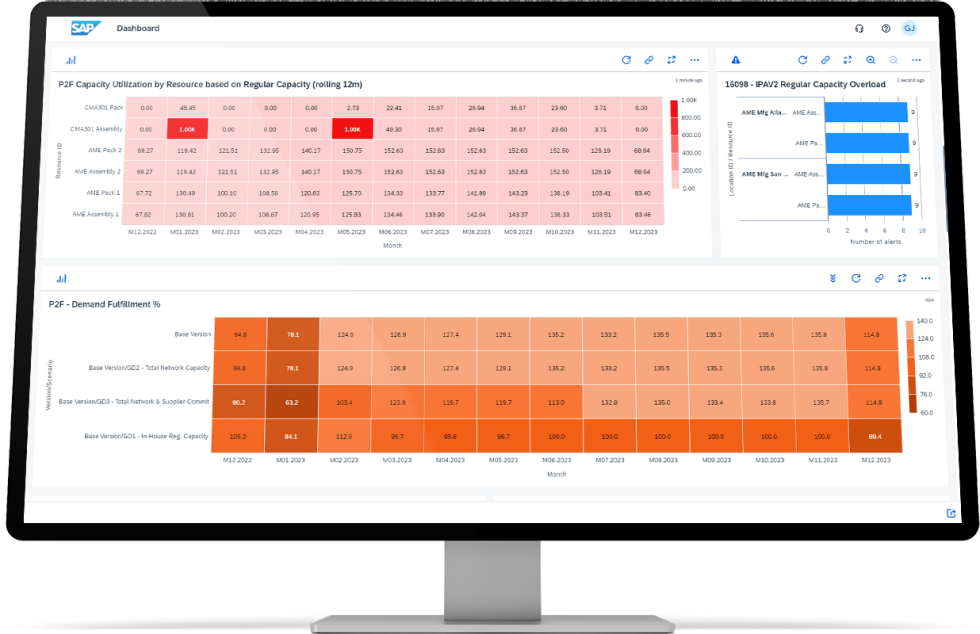

Sales and Operations Planning (S&OP)

Real-time planning

Balance demand and supply, integrate planning across finance and operations, and link execution to mid- and long-term plans.

Simulation and comparison of scenarios

Run what-if analyses on demand or supply changes and compare scenarios for fast, informed decisions that mitigate risk.

Collaboration

Break down operational and planning silos and improve teamwork and efficiency in the planning process.

Performance monitoring

Measure actual performance against plans and monitor for future misalignment between operational and strategic plans.

Forecasting and Demand Management

Demand planning

Combine multiple demand signals with statistical forecasts and collaborate to create accurate demand plans.

Advanced demand sensing

Refine short-term forecasts to drive better fulfilment and inventory reduction.

Robust statistical models

Use sophisticated forecasting algorithms combined with machine learning and pre-and post-processing algorithms.

Time-series analysis

Classify products based on historical patterns and select algorithms based on that classification.

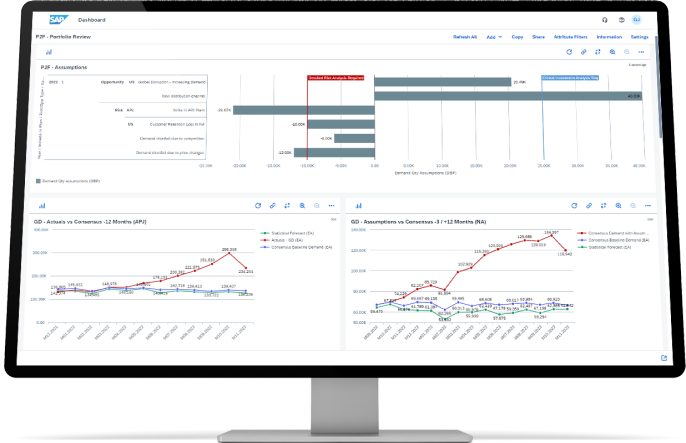

Inventory Planning and Optimization

Multistage inventory optimization

Use less inventory to buffer supply chain risk and uncertainty with multi-echelon inventory optimization.

Robust statistical models

Provide significant improvements over textbook calculations with proven algorithms.

Forecast error management

Buffer against forecast error and other demand-side uncertainty to support your demand-driven supply chain.

Embedded analytics

Visualize your supply chain network and quickly gain insights into inventory drivers.

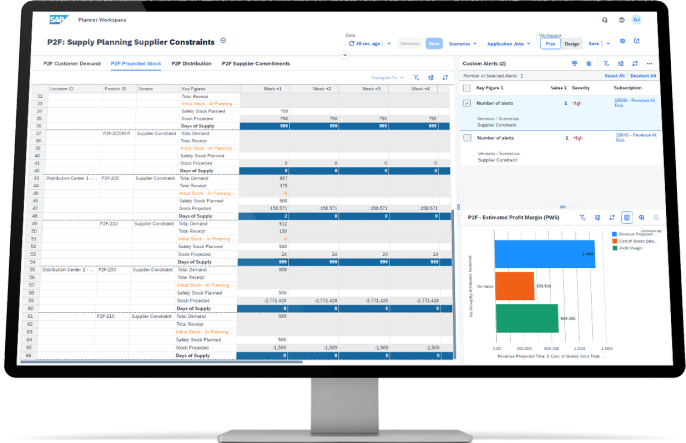

Response and Supply Planning

Multilevel planning

Model across locations and multilevel bills of material to cover the entire supply chain network.

Supply planning

Utilize a constrained or unconstrained heuristic-based or optimization technique to develop a tactical supply plan.

Rough-cut planning

Develop a tactical rough-cut capacity plan and consider capacity and material constraints simultaneously.

Response management

Create an operational or order-based supply plan and manage allocations and repromising of orders with prioritization rules.

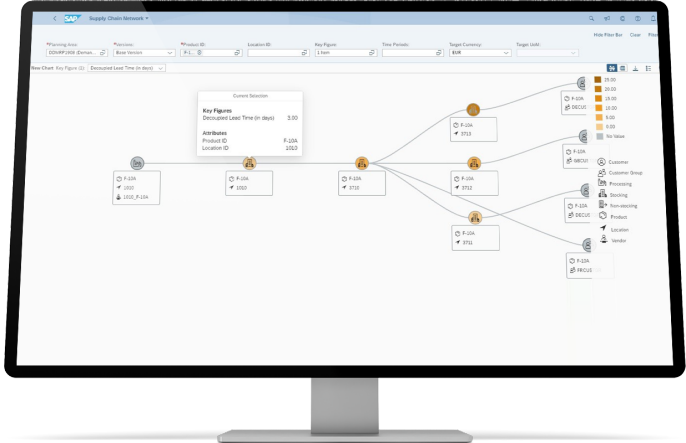

Demand-Driven Replenishment

Smooth material and information flow

Break the bullwhip effect in your supply chain and calm supply chain nervousness.

Replenishment based on actual demand

Minimize the impact of incorrect forecasts on your replenishment strategy.

Calculation of decoupled inventory buffers

Use past material consumption or future forecasts to determine the size of inventory buffer zones.

Supply chain resilience

Buffer supply and demand uncertainty through decoupling points across the supply chain.

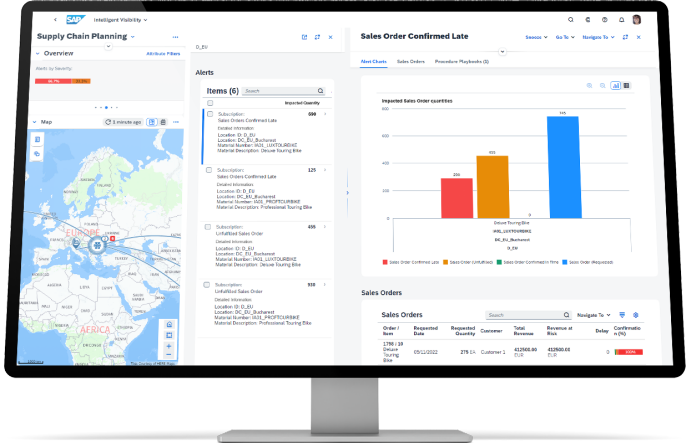

Supply Chain Visibility

Intelligent visibility into your supply chain

View your supply chain as a network with the exceptions that impact performance.

Simulation and comparison scenarios

Run simulations of demand or supply changes for what-if analysis and compare scenarios for fast, informed decisions.

Event-driven exception management

Identify issues quickly with customer alerts, providing context and priority information.

Supply network collaboration

Work with suppliers and outsourced manufacturers for easier and faster planning.